Control Systems Development and Retrofit

Control system development requires three distinct technical attributes:

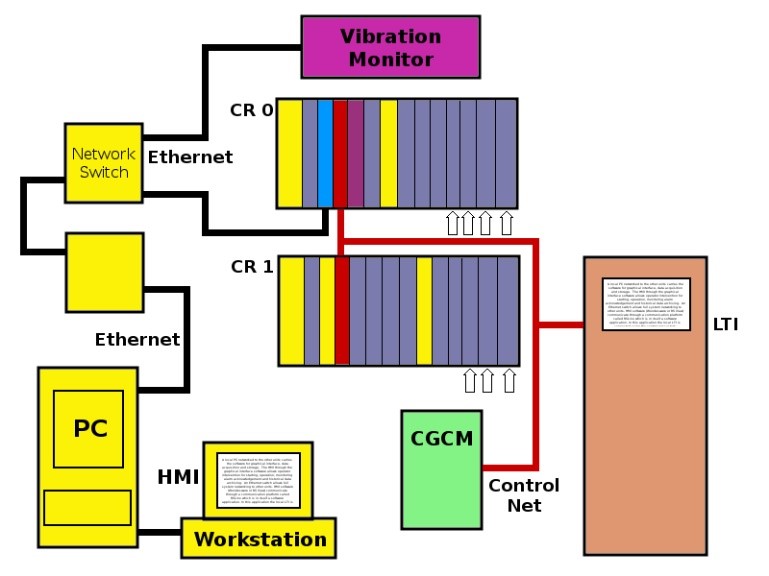

System Architecture

Expertise to design the control platform and define the signals entering the system. These include digital, analogue and a variety of data links. The engineer must be fully versed in the system as it was and know exactly how it worked in the past.

Using the control specifications and the hardware connection detail, a set of electrical schematics and wiring diagrams are developed. The development must take into consideration advances in signal processing and the speed at which information is now gathered.

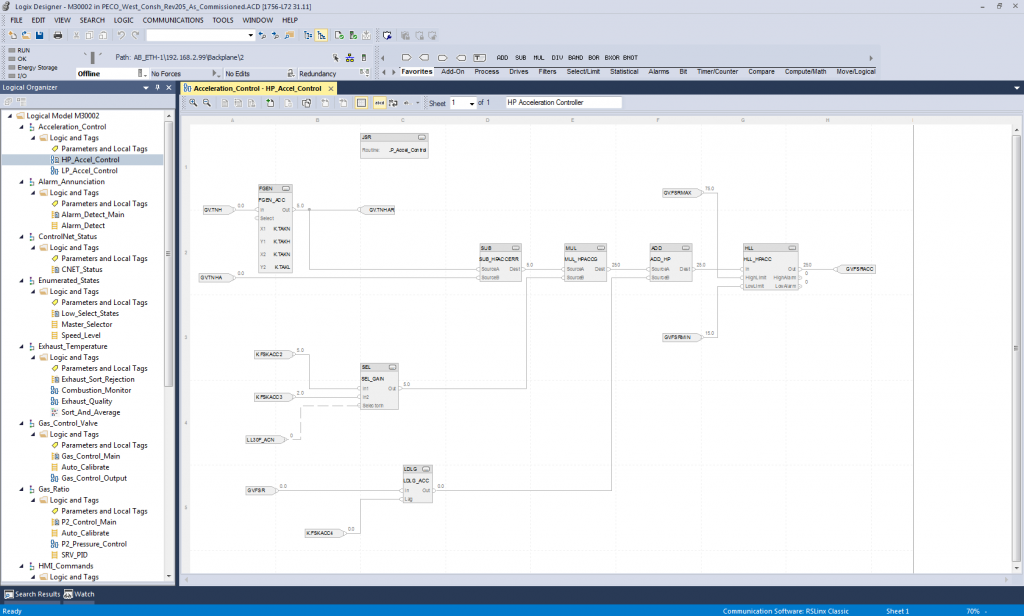

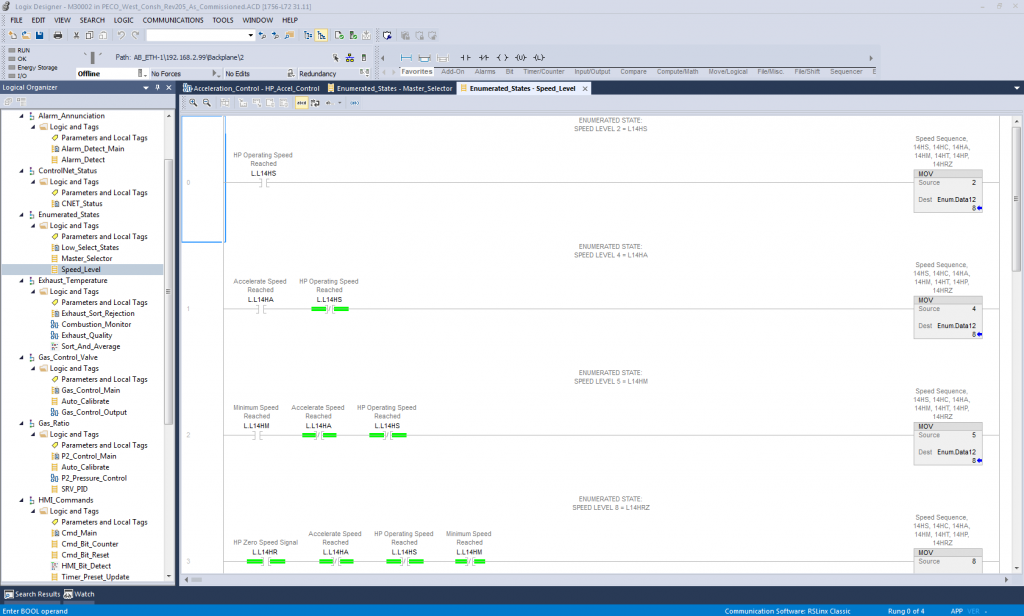

Control Coding Development

Original control code may be in the form of ladder logic or with very old equipment it may be relay-based. The controls engineer defines the logic and sequencing taken from the old code and implements it into the new control platform.

Dynamic Controls develop control code using Control Logix 5000. Written in a combination of ladder and function block Logic, this versatile control system architecture is effective and transparent.

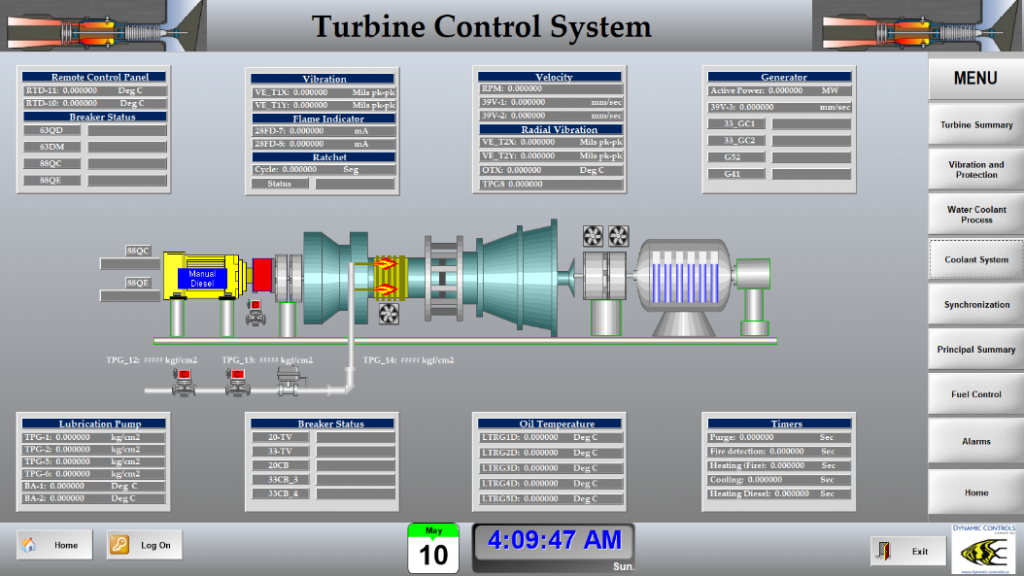

HMI

The human machine interface (HMI) graphics differ from location to location, and this portion of the development frequently solicits substantial input from the customer. The system integrator works hand in hand with the controls engineer. A gas turbine project requires one graphic per subsystem totalling up to twenty animated graphics.

Our solutions are Smart Reliable Feasible

Project Example

This is Cactus project Unit 3 . Dynamic Controls developed the control system utilizing both Ethernet and Control net.